Abstract

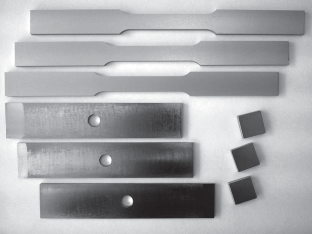

The results of a study of the resistance to fatigue fracture of the sheets made of the heat-resistant titanium alloys VT18U (Ti–6.5Al–4.3Zr–2.4Sn–0.8Nb–0.7Mo–0.1Si, wt %), VT8 (Ti–6.4Al–3.4Mo–0.3Si, wt %), and VT25U (Ti–6.51Al–3.76Zr–1.71Sn–3.94Mo–0.5W–0.13Si, wt %) have been presented. Fatigue curves have been obtained in the initial state and in the oxidized one after isothermal annealing at a temperature of 560°C for 1000 h in air. It has been established that after annealing, the fatigue resistance of all oxidized alloys in the low-cycle region decreases by an order of magnitude. The fatigue limit of the oxidized alloys VT18U and VT25U does not change and is of about 320 MPa. The high-cycle fatigue limit of the VT8 alloy decreases from 300 MPa in the initial state to 230 MPa in the oxidized state. It has been established that after annealing, the phase composition of an oxide of 250 nm in thickness on the surface of the alloys is different and contains the phases of anatase and rutile for the VT18U and VT25U alloys and contains predominantly rutile for the VT8 alloys, which is why the fatigue limit of the oxidized alloys differs.

REFERENCES

V. N. Moiseev, “Titanium in Russia,” Met. Sci. Heat Treat. 47, 371–376 (2005). https://doi.org/10.1007/s11041-005-0080-9

T. V. Pavlova, O. S. Kashapov, and N. A. Nochovnaya, “Titanium alloys for gas turbine engines,” Vse Mater. Entsiklopedicheskii Sprav., No. 5, 8–14 (2012).

V. G. Antashev, N. A. Nochovnaya, T. V. Pavlova, and V. I. Ivanov, “Titanium superalloys,” Vse Mater. Entsiklopedicheskii Sprav., No. 3, 7–8 (2007).

A. A. Il’in, B. A. Kolachev, and I. S. Pol’kin, Titanium Alloys: Composition, Structure, Properties: Handbook (VILS, Moscow, 2009) [in Russian].

M. S. Kalienko, M. O. Leder, A. V. Volkov, A. V. Berestov, and A. V. Zhelnina, “Investigation of structure and mechanical properties of sheets made of Ti alloys such as VT8, VT18U and VT25U in heat-treated state,” Tekhnol. Legkikh Splavov, No. 4, 37–41 (2017).

N. M. Pul’tsin, Interaction of Titanium with Gases (Metallurgiya, Moscow, 1969) [in Russian].

B. Geary, V. J. Bolam, S. L. Jenkins, and D. P. Davies, “High temperature titanium sheet for helicopter ex-haust applications,” in Ti’1995: Science and Tecnol. Proc. 8-th World Conf. of Titanium (1995), pp. 1638–1645.

R. Gaddam, M.-L. Antti, and R. Pederson, “Influence of alpha-case layer on the low cycle fatigue properties of Ti–6Al–2Sn–4Zr–2Mo alloy,” Mater. Sci. Eng., A 599, 51–56 (2014). https://doi.org/10.1016/j.msea.2014.01.059

J. E. King, “Role of oxides in fatigue crack propagation,” Mater. Sci. Technol. 6, 19–31 (1990). https://doi.org/10.1179/026708390790189416

M. Hagiwara, T. Kitashima, and S. Emura, “Relationship between microstructures, facet morphologies at the high-cycle fatigue (HCF) crack initiation site, and HCF strength in Ti-6242S,” Mater. Sci. Eng., A 727, 43–50 (2018). https://doi.org/10.1016/j.msea.2018.04.043

P. J. Ashton, T.-S. Jun, Z. Zhang, T. B. Britton, A. M. Harte, S. B. Leen, and F. P. E. Dunne, “The effect of the beta phase on the micromechanical response of dual-phase titanium alloys,” Int. J. Fatigue 100, 377–387 (2017). https://doi.org/10.1016/j.ijfatigue.2017.03.020

A. Leoni, I. Apachitei, A. C. Riemslag, L. E. Fratila-Apachitei, and J. Duszczyk, “In vitro fatigue behavior of surface oxidized Ti35Zr10Nb biomedical alloy,” Mater. Sci. Eng., C 31, 1779–1783 (2011). https://doi.org/10.1016/j.msec.2011.08.010

I. Apachitei, B. Lonyuk, L. E. Fratila-Apachitei, J. Zhou, and J. Duszczyk, “Fatigue response of porous coated titanium biomedical alloys,” Scr. Mater. 61, 113–116 (2009). https://doi.org/10.1016/j.scriptamat.2009.03.017

I. Apachitei, A. Leoni, A. C. Riemslag, L. E. Fratila-Apachitei, and J. Duszczyk, “Enhanced fatigue performance of porous coated Ti6Al4V biomedical alloy,” Appl. Surf. Sci. 257, 6941–6944 (2011). https://doi.org/10.1016/j.apsusc.2011.03.038

M. Y. P. Costa, M. L. R. Venditti, M. O. H. Cioffi, H. J. C. Voorwald, V. A. Guimarães, and R. Ruas, “Fatigue behavior of PVD coated Ti–6Al–4V alloy,” Int. J. Fatigue 33, 759–765 (2011). https://doi.org/10.1016/j.ijfatigue.2010.11.007

Ya. Bai, T. Guo, J. Wang, J. Gao, K. Gao, and X. Pang, “Stress-sensitive fatigue crack initiation mechanisms of coated titanium alloy,” Acta Mater. 217, 117179 (2021). https://doi.org/10.1016/j.actamat.2021.117179

Ya.-Yu. Bai, J. Gao, T. Guo, K.-W. Gao, A. A. Volinsky, and X.-L. Pang, “Review of the fatigue behavior of hard coating-ductile substrate systems,” Int. J. Miner., Metall. Mater. 28, 46–55 (2021). https://doi.org/10.1007/s12613-020-2203-0

A. A. Gribb and J. F. Banfield, “Particle size effects on transformation kinetics and phase stability in nanocrystalline TiO2,” Am. Mineral. 82, 717–728 (1997). https://doi.org/10.2138/am-1997-7-809

I. Jouanny, S. Labdi, P. Aubert, C. Buscema, O. Maciejak, M.-H. Berger, V. Guipont, and M. Jeandin, “Structural and mechanical properties of titanium oxide thin films for biomedical application,” Thin Solid Films 518, 3212–3217 (2010). https://doi.org/10.1016/j.tsf.2009.09.046

O. Zywitzki, T. Modes, H. Sahm, P. Frach, K. Goedicke, and D. Glöß, “Structure and properties of crystalline titanium oxide layers deposited by reactive pulse magnetron sputtering,” Surf. Coat. Technol. 180–181, 538–543 (2004). https://doi.org/10.1016/j.surfcoat.2003.10.115

J. Lin, B. Wang, W. D. Sproul, Yi. Ou, and I. Dahan, “Anatase and rutile TiO2 films deposited by arc-free deep oscillation magnetron sputtering,” J. Phys. D: Appl. Phys. 46, 084008 (2013). https://doi.org/10.1088/0022-3727/46/8/084008

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation within the framework of the Program of Development of the Ural Federal University in accordance with the strategic academic leadership program “Prioritet (priority)–2030.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Translated by N. Podymova

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kalienko, M.S., Popov, A.A., Volkov, A.V. et al. Fatigue Resistance of the Sheets of Heat-Resistant Titanium Alloys. Phys. Metals Metallogr. 125, 332–339 (2024). https://doi.org/10.1134/S0031918X23603141

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X23603141