‘Plyscrapers’: The rise of the wooden skyscraper

C.F. Møller / Dinell Johansson

C.F. Møller / Dinell JohanssonTimber skyscrapers are sprouting up across the globe, from Vancouver to Vienna. Are they strong enough? Will they rot? And won't they burn down?

When the Ingalls Building in Cincinnati, Ohio was unveiled in 1903, no one believed it would still be standing over a century later. In fact, it wasn’t expected to last the night.

The towering, 16-storey behemoth was the first concrete skyscraper in world history. Previously they had been made with burly metal alloys such as steel – concrete was extremely experimental. The media ran wild with speculation.

Some said it would crack and crumble under its own weight. Others even suggested it might be blown over. Legend has it that when the supports were removed, a local reporter stayed awake through the night, hoping to scoop the story of its collapse the very next morning.

In 2017 we’re on the cusp of a new revolution: wooden skyscrapers. It sounds completely ludicrous, like a modern twist on the construction fable the Three Little Pigs. But it’s really happening. Are they strong enough? Will they rot? And won’t they burn down?

“Oh wood has some big advantages – how long do you have?” says Ola Jonsson, an associate partner at CF Möller Architects, which won a competition for their design of a 34-storey wooden building.

For a start they’re quicker to build, since even steel skyscrapers have concrete floors which can take weeks to dry. That’s several weeks per floor. On the other hand wood panels can be sliced to exact dimensions in the factory and then slotted into place within a matter of hours.

Then there’s the issue of weight. For a long time Murray Grove, a nine-storey housing block in Hackney, was the highest in the world. “If we’d made it from concrete it would have taken 900 HGVs [heavy goods vehicles] rumbling through London to deliver all the material,” says Anthony Thistleton, a founding director of Waugh Thistleton Architects who designed the building. In the end it took only 100.

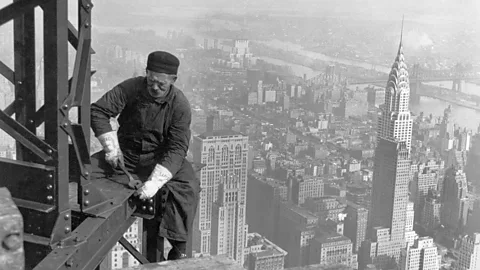

Wikimedia Commons/Lewis Hine

Wikimedia Commons/Lewis HineThat’s not to mention the environmental benefits. Though we don’t tend to think of the carbon footprint of our buildings, concrete and steel are secret super-villains, thought to be responsible for about 8% and 5% of global emissions respectively. On the other hand trees actively suck in carbon dioxide and lock it away in their wood.

Today wooden skyscrapers are sprouting up across the globe, from Norway to New Zealand. There’s the 18-storey T3 project in Minneapolis, made from pine felled by mountain pine beetles, a tiny insect pest that lives in their bark; the €60m (£44m/$58m) HoHo tower, a sleek spruce confection currently under construction in Vienna; and the lofty 133m (436ft) Trätoppen proposed for Stockholm. Translating as “the treetop” in Swedish, it would sit on top of a 1960s carpark.

As you’d expect, insurance companies aren’t delighted, but a small band of renegade architects is determined to lead us into a wood renaissance nevertheless. Together they envisage entire cities of timber buildings – “We want to talk on that level,” says Jonsson – complete with forests of mighty plywood skyscrapers, affectionately known as plyscrapers.

Timber may be the most advanced building material of the 21st Century, but it’s not like we invented it. The Sakyamuni Pagoda of Fogong Temple in China is one of the oldest wooden structures. It was built by Emperor Daozong of the Liao Dynasty at the site of his grandmother’s home – without a single nail, screw or bolt.

And yet, thanks to skilful craftsmanship and sturdy design, the pagoda is still standing 900 years later. At 67m (219ft) high, it remains the tallest timber building in the world – at least, until the HoHo building is completed. It has survived at least seven serious earthquakes, including one in 1556 that killed nearly a million people. This makes a lot of sense, since wood is famously flexible. When the ground starts shaking, wooden structures tend to sway without collapsing. In earthquake-prone areas such as New Zealand, the majority of houses are wooden.

For millennia, forests were often the only building material around. In medieval England, houses, offices, forts, factories, cathedrals and even castles were all made of wood. Raw timber is incredibly resilient – it doesn’t rot unless you get it wet. “If you can keep it dry it will last forever,” says Andy Buchanan, a leading structural engineer from PTL consultants in New Zealand.

Many ancient wooden buildings are found in miserable climates, from Britain’s rustic Tudor houses of oak to Norway’s fairy-tale stave churches, carved from a special type of fir called "malmfuru". The former were typically given a wattle and daub coating of wooden strips covered in straw mixed with mud or animal dung, while staves were raised above the ground to keep them dry.

Alamy

Alamy“Now we enclose the structural wood in a weathertight envelope, such as glass or fabric. Or if you want the building to look woody, you can use cladding,” says Buchanan.

The main reason there aren’t legions of super-old timber buildings is fire. In the wood-age, nearly every city had its own giant fire. In AD 64 there was the Great Fire of Rome, which lasted for six days. In 1657, there was the Great Fire of Meireki, which scorched the capital city of Edo (now Tokyo) and claimed over 100,000 lives. In the US there were fires in New York City, Chicago, Washington and San Francisco.

In London the major shift came after the Great Fire of 1666, which destroyed tens of thousands of buildings. It heralded a new era of regulations and the city was rebuilt in stone and brick. Is going back to wood a terrible mistake?

As it happens, it isn’t straight-up wood. “The tall buildings I’m talking about are made out of engineered wood – small pieces of wood glued together,” says Buchanan. There are three main types. “There’s glued laminated timber, glulam, which is used for straight beams and columns. It’s been around for 50 years or more. Then there’s laminated veneer lumber, LVL, which has the same strength as concrete. But the newest material is cross-laminated timber (CLT), which is really starting to take off now.”

CLT is a true wonder material. Made from thin layers of wood criss-crossed and stuck together with fire-resistant glue, this “plywood on steroids” is claimed to be as strong as structural steel; alternating the direction of the grain offsets the weaknesses in any given plank and stops the material warping if it gets wet. It’s made into massive, flat panels up to six metres (20ft) wide and 20 inches (50cm) thick that can be used whole, to form entire walls, floors or part of a roof.

The size of the panels is crucial. “If you’re making a fire, everyone knows you don’t start with giant logs,” says Thistleton. “It would take a lot to ignite them. The first thing that happens is they char and that actually protects the wood beneath.”

Alamy

AlamyIf you need a bit more reassurance, take a study by the Committee on Tall Wood Buildings earlier this year. The test was conducted at the Fire Research Laboratory, Virginia, a state-of-the-art facility that basically lets scientists set things on fire and then watch what happens. When they set alight two one-bedroom apartments made of engineered wood, the fire raged until it had burnt through the furnishings, then extinguished itself. The contents were turned to ash, but the structure itself charred and remained intact.

Other than preventing the spread of a fire, one of the most important factors is what happens to CLT when it’s heated. In this respect, the material wins hands down over steel and concrete, which tend to melt and weaken. “There’s an image that we often use in our lectures. It’s a devastated fire site with a big timber column supporting a timber beam. At the top is a steel beam that’s completely melted,” says Thistleton.

As the tragedy at Grenfell tower showed earlier this year, fire resistance is even more of a challenge in tall buildings, which are harder for firefighters to reach. According to Buchanan, this is one of the reasons wooden buildings typically tend to have fewer than 10 storeys.

Right now the tallest is Brock Commons, a residential building at the University of British Columbia. The lift shaft and stairwell is made of concrete, but all the beams and columns and floors are made of wood. “As you enter the building you don’t see any wood at all. That’s because of fire safety – it’s all covered with fire-proof gypsum board,” he says.

Besides, lofty heights bring a range of other issues. The main concern for most skyscrapers is their sheer weight. The material they’re built from has to be strong enough to support its own bulk, or the structure will collapse – the very reason everyone was so worried about the Ingalls Building back in the early 20th Century.

But wooden buildings are so light, the main challenge isn’t keeping them up, but holding them down. As you get higher up, wind becomes faster – at the top of the tallest building in the world, the Burj Khalifa in Dubai, the wind can reach 150km/h (90mph). These lateral forces have been plaguing skyscrapers for years and are the leading factor in their structural design.

The heavier the building, the better. In strong winds, Trump Tower in New York had a nausea-inducing – but perfectly safe – amount of sway until it was reinforced with concrete columns in 1995. One way to overcome this in wooden buildings is to give them a concrete core, but some architects see this as cheating.

C.F. Møller

C.F. MøllerWhich brings us to the second problem. Though panels of engineered wood are exceptionally strong individually, there’s the big challenge of how to attach them together. At these scales, nails and screws don’t cut it. “To stop the building blowing over you need lots and lots of walls and floors,” says Buchanan.

In residential buildings, this isn’t a problem, since ceilings don’t need to be so high and architects can carve out the building into a honeycomb of separate rooms. But open-plan environments such as offices and shops are a real test. Over a certain height, these buildings tend to need some more heavy-duty anchoring, such as steel bars that run all the way from the bottom to the top of the building.

These are just some of the reasons that, if we’re being pedantic, technically there aren’t actually any wooden skyscrapers yet. The Emporis Standards Committee, a database for building information, says skyscrapers should be at least 100m (330ft). That’s well above the height of any wooden building currently planned.

For Thistleton, the current fashion for building upwards with wood is about showing off. “We should be building in timber for environmental reasons,” he says. “The need to build the highest is just a manifestation of the ego of the architect.” In addition to locking away CO2, wood buildings have much better environmental credentials all round. At Murray Grove in Hackney, people aren’t using their heating because the wood is such a good insulator.

Jonsson agrees. “It would be great to do a 100m-tall building out of wood. We’ve done the calculations and it’s theoretically possible, but there are some major challenges. The important thing is that just one cubic metre of wood sequesters a ton of CO2.”

“The 20th Century was the concrete age, it was all about the dominion of man over nature. Now we’re transitioning towards a different attitude, a more nurturing one,” says Thistleton. Welcome back, perhaps, to the age of wood.

--

To comment on and see more stories from BBC Designed, you can follow us on Facebook, Twitter and Instagram.

If you liked this story, sign up for the weekly bbc.com features newsletter, called “If You Only Read 6 Things This Week”. A handpicked selection of stories from BBC Future, Earth, Culture, Capital, and Travel, delivered to your inbox every Friday.