鋯鈦酸 鉛

| 鋯鈦 | |

|---|---|

| |

| IUPAC 鋯鈦 | |

| 别名 | 鈦鋯 |

| 识别 | |

| CAS |

12626-81-2 |

| PubChem | 159452 |

| SMILES |

|

| Pb[Zr xTi 1-x]O 3 (0≤x≤1) | |

| 303.065 ~ 346.4222 g/mol g·mol⁻¹ | |

| 危险 | |

GHS危险

| |

| GHS |

危险 |

| H-术语 | H302, H332, H360, H373, H410 |

| P-术语 | P201, P202, P260, P261, P264, P270, P271, P273, P281, P301+312, P304+312, P304+340, P308+313, P312 |

鋯鈦

xTi

1-x]O

3(0≤x≤1),

鋯鈦

電 陶 瓷特性

[编辑]Being piezoelectric, lead zirconate titanate develops a voltage (or potential difference) across two of its faces when compressed (useful for sensor applications), and physically changes shape when an external electric field is applied (useful for actuator applications). The relative permittivity of lead zirconate titanate can range from 300 to 20000, depending upon orientation and doping.[

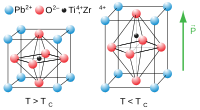

Being pyroelectric, this material develops a voltage difference across two of its faces under changing temperature conditions; consequently, lead zirconate titanate can be used as a heat sensor. Lead zirconate titanate is also ferroelectric, which means that it has a spontaneous electric polarization (electric dipole) that can be reversed in the presence of an electric field.

The material features an extremely large relative permittivity at the morphotropic phase boundary (MPB) near x = 0.52.[3]

Some formulations are ohmic until at least 250 kV/cm (25 MV/

Uses

[编辑]

Lead zirconate titanate-based materials are components of ceramic capacitors and STM/AFM actuators (tubes).

Lead zirconate titanate is used to make ultrasound transducers and other sensors and actuators, as well as high-value ceramic capacitors and FRAM chips. Lead zirconate titanate is also used in the manufacture of ceramic resonators for reference timing in electronic circuitry. In 1975 Sandia National Laboratories created anti-flash goggles featuring PLZT to protect aircrew from burns and blindness in case of a nuclear explosion.[6] The PLZT lenses could turn opaque in less than 150 microseconds.

Commercially, it is usually not used in its pure form, rather it is doped with either acceptors, which create oxygen (anion) vacancies, or donors, which create metal (cation) vacancies and facilitate domain wall motion in the material. In general, acceptor doping creates hard lead zirconate titanate, while donor doping creates soft lead zirconate titanate. Hard and soft lead zirconate titanate generally differ in their piezoelectric constants. Piezoelectric constants are proportional to the polarization or to the electrical field generated per unit of mechanical stress, or alternatively is the mechanical strain produced by per unit of electric field applied. In general, soft lead zirconate titanate has a higher piezoelectric constant, but larger losses in the material due to internal friction. In hard lead zirconate titanate, domain wall motion is pinned by the impurities, thereby lowering the losses in the material, but at the expense of a reduced piezoelectric constant.

Varieties

[编辑]One of the commonly studied chemical composition is PbZr

0.52Ti

0.48O

3. The increased piezoelectric response and poling efficiency near to x = 0.52 is due to the increased number of allowable domain states at the MPB. At this boundary, the 6 possible domain states from the tetragonal phase ⟨100⟩ and the 8 possible domain states from the rhombohedral phase ⟨111⟩ are equally favorable energetically, thereby allowing a maximum 14 possible domain states.

Like structurally similar lead scandium tantalate and barium strontium titanate, lead zirconate titanate can be used for manufacture of uncooled staring array infrared imaging sensors for thermographic cameras. Both thin film (usually obtained by chemical vapor deposition) and bulk structures are used. The formula of the material used usually approaches Pb

1.1(Zr

0.3Ti

0.7)O

3 (called lead zirconate titanate 30/70). Its properties may be modified by doping it with lanthanum, resulting in lanthanum-doped lead zirconium titanate (lead zirconate titanate, also called lead lanthanum zirconium titanate), with formula Pb

0.83La

0.17(Zr

0.3Ti

0.7)

0.9575O

3 (Lead zirconate titanate 17/30/70).[7]

另見

[编辑]參考

[编辑]- ^ What is "Lead zirconium titanate"?. americanpiezo.com. APC International. [April 29, 2021]. (

原始 内容 存 档于2018-08-27). - ^ Bell, Andrew J.; Deubzer, Otmar. Lead-free piezoelectrics—The environmental and regulatory issues. MRS Bulletin. August 2018, 43 (8): 581–587 [2022-08-28]. ISSN 0883-7694. doi:10.1557/mrs.2018.154. (

原始 内容 存 档于2022-08-15) (英 语). - ^ Rouquette, J.; Haines, J.; Bornand, V.; Pintard, M.; Papet, Ph; Bousquet, C.; Konczewicz, L.; Gorelli, F. A.; Hull, S. Pressure tuning of the morphotropic phase boundary in piezoelectric lead zirconate titanate. Physical Review B. 2004, 70 (1): 014108. doi:10.1103/PhysRevB.70.014108.

- ^ Moazzami, Reza; Hu, Chenming; Shepherd, William H. Electrical Characteristics of Ferroelectric Lead zirconate titanate Thin Films for DRAM Applications (PDF). IEEE Transactions on Electron Devices. September 1992, 39 (9): 2044 [2022-08-28]. doi:10.1109/16.155876. (

原始 内容 存 档 (PDF)于2015-09-24). - ^ Andersen, B.; Ringgaard, E.; Bove, T.; Albareda, A.; Pérez, R. Performance of Piezoelectric Ceramic Multilayer Components Based on Hard and Soft Lead zirconate titanate. Proceedings of Actuator 2000. 2000: 419–422.

- ^ Cutchen, J. Thomas; Harris, Jr., James O.; Laguna, George R. PLZT electrooptic shutters: applications. Applied Optics. 1975, 14 (8): 1866–1873 [2022-08-28]. PMID 20154933. doi:10.1364/AO.14.001866. (

原始 内容 存 档于2015-02-11). - ^ Liu, W.; Jiang, B.; Zhu, W. Self-biased dielectric bolometer from epitaxially grown Pb(Zr,Ti)O3 and lanthanum-doped Pb(Zr,Ti)O3 multilayered thin films. Applied Physics Letters. 2000, 77 (7): 1047–1049. doi:10.1063/1.1289064.

外部 鏈接

[编辑]

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| |||||||||||||||||||